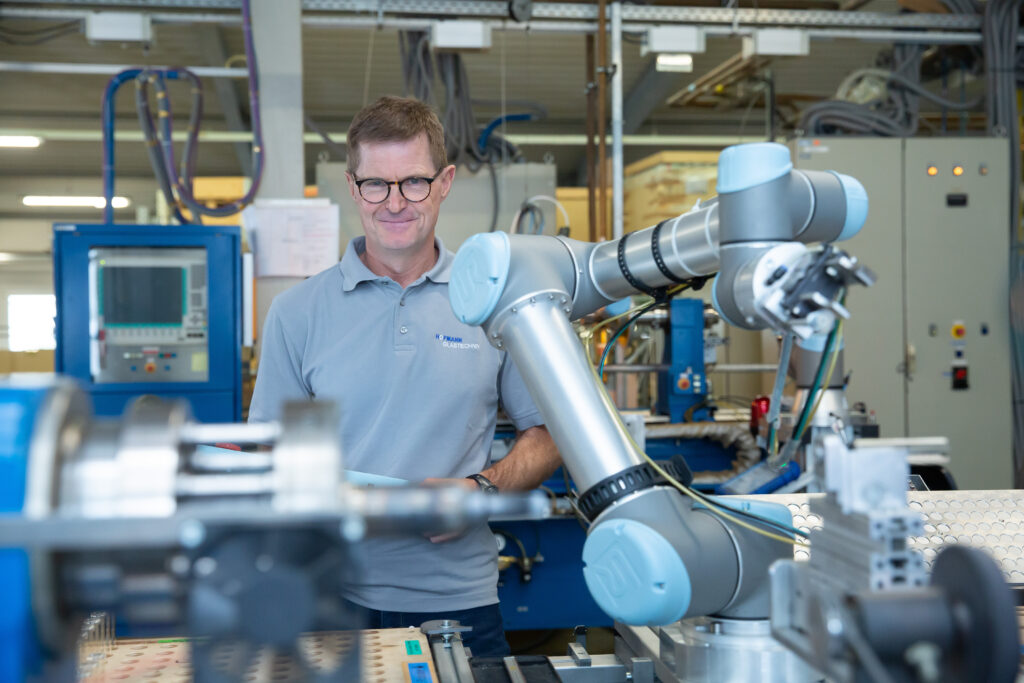

Collaborative Robots

Accelerate Automation with Collaborative Robots

Collaborative robots (cobots) are cost-effective, simple-to-deploy robots that improve quality and efficiency.

Designed to automate repetitive and dangerous work – including machine tending, packaging and palletizing, assembly, material processing, screw and nut driving and more – cobots make the workplace safer and more efficient.

Teradyne’s collaborative automation solutions company, Universal Robots (UR), brings flexible and straightforward to program robots to businesses of every size, all over the world.

Automation for Anyone. Anywhere.

Collaborative automation solutions give manufacturers access to all the benefits of advanced robotic automation, without the extra costs associated with traditional robots – difficult programming, long setup and fenced work cells. This makes automation accessible and affordable, even for small-batch production runs and mixed product assembly.

Making Automation Easier than Ever

Usage of cobots spans industries and applications and offers a flexible solution for a wide range of use cases. These human-scale robots are easy to deploy and redeploy to keep pace with changing needs industry such as automotive, food and beverage, metal and machining or electronics.

Benefits of Collaborative Robots

Improved workforce

Cobots automate and streamline repetitive processes, so staff can be assigned to jobs that provide them with new challenges. By automating highly repetitive tasks, cobots give your team more time to think critically, innovate and make better use of existing resources. The result – better performance, and more importantly, higher levels of satisfaction and employee retention.

Straightforward programming

UR’s intuitive software, PolyScope, enables anyone, from developers to operators, to program a cobot and have an application up and running within a few hours.

Fast ROI

Cost effective, easy-to-deploy and flexible, cobots offer manufacturers a fast path to automation. Cobots require a lower initial investment than traditional robotics and have an average payback time of 12-18 months.

Versatile deployment

Cobots’ high degree of flexibility allows customers to change the task and pace of the cobot according to production demands.

Collaborative-capable safety functions

Following a risk assessment, most cobots can seamlessly operate alongside employees, assisting with dull, dirty, and dangerous tasks and in applications unattainable by traditional robots and production equipment. This way, cobots help reduce workplace injuries and alleviate the heavy financial and operational toll placed on manufacturers.

Universal Robots

Universal Robots is a leading provider of collaborative robots (cobots) used across various industries, including automotive, food & beverage, metal & machining, electronics, pharmaceutical, and in education. Founded in 2005 and headquartered in Odense, Denmark, Universal Robots aims to create a world where people work with robots, not like robots.

Collaborative Robot Arms

Since introducing the world’s first commercially viable cobot in 2008, Universal Robots has sold over 75,000 cobots worldwide and has developed a product portfolio reflecting a range of reaches and payloads, including the UR3e, UR5e, UR10e, UR16e, UR20, and UR30 robots. All models are lightweight yet built and tested to withstand tough industrial environments.

UR’s cobot arms are easy to deploy and straightforward to program, enabling manufacturers to deploy robots into existing production setups without significant disruption in a matter of days, not weeks. They are flexible and can be adjusted and programmed to add value to any environment by taking over repetitive, high-precision tasks.

Proven to drive profitability, performance and safety, UR cobots work in the most rigorous production environments to deliver the ROI manufacturers need.

Visit Universal Robots to learn more.

Providing Choice and Innovation

An extensive ecosystem has grown around the UR cobot technology, fostering innovation, and providing choice for customers globally. The more than 1000 Universal Robots partners offer components, software, application kits, and standardized solutions that enable any application.

Collaborative Robot Applications

From assembly to final product – no matter the processing task – collaborative robots can help you achieve greater productivity to remain competitive.

Assembly

Screwdriving | Part Insertion

Produce repeatable, accurate assembly processes such as screw driving, part fitting and insertion.

Dispensing

Gluing | Sealing | Painting

Reduce waste and increase accuracy of dispensing applications with force/torque sensing.

Finishing

Sanding | Polishing

Ensure consistent polishing and buffing with force control that automatically adjusts to achieve the desired force.

Machine Tending

CNC | Injection Mold | ICT

Improve speed and quality while relieving machine operators from physically demanding, repetitive work.

Material Handling

Packaging | Palletizing | Bin Picking

Pick up a wide range of objects even in unstructured environments such as a bins or totes.

Material Removal

Grinding | Deburring | Drilling

Optimize your material removal tasks with consistent and precise placement of the tool.

Quality Inspection

Testing | Inspecting | Measuring

Consistently follow processes with minimal deviation for optimum conditions for study and analysis.

Welding

Arc | Soldering

Increase accuracy, while improving workplace safety by allowing a robot to handle dangerous tasks.

Committed to Every Customer’s Success

UR offers a comprehensive customer experience that includes UR Academy, an acclaimed training platform accessible online or in person at over 120 training centers globally. Alongside, our service offerings are meticulously crafted to minimize downtime, create value, and accelerate customer success.

Concentrated Industry and Application Knowledge

Universal Robots has recently established global Centers of Excellence for Welding, Palletizing, and Machine Tending applications. These centers, led by subject matter experts, serve as knowledge hubs, offering expert recommendations and guidance on the latest trends in the field to UR partners and customers worldwide.

Teradyne’s Expanding Portfolio of Robotics

Teradyne acquired Universal Robots in 2015. Along with Mobile Industrial Robots (MiR), they comprise Teradyne Robotics.