ETS-88

Test System Optimized for High Throughput, Low Cost of Test for Single Site, Multi-site and Index Parallel Applications

The ETS-88 is an optimal test platform for testing a wide variety of devices including: simple analog, high precision, high voltage, high current / power, automotive, video, audio, complex mixed-signal, as well as emerging power processes like SiC and GaN. The ETS-88 test system hardware is designed to provide independent floating resources per site to avoid resource sharing across sites while improving site-to-site isolation and measurement accuracy.

Advantages

Multi Test Head design supports high parallel test efficiency, capable of testing up to four unique DUTs per test system in 1 square meter of floor space. Each test head offers up to 72 analog channels and up to 32 digital channels (66/132 MHz).

Industry leading EV software operating from a dual quad core CPU controller supporting both index parallel and multi-site test.

Fully compatible with ETS’s line of Digital and Floating SmartPin™ Resources.

Test system PC runs on familiar MS WindowsTM operating system and executes programs from C++ Visual StudioTM environment.

Applications

Power Management

- Low dropout regulators, DC-DC converters, voltage regulators, boost regulators, multi-phase PWMs, battery chargers, hot swap power managers, gate drivers

Precision Analog

- Op amps, instrument amplifiers, video amplifiers, audio amplifiers

automotive - Fuel injectors, ABS controllers, airbag controllers, automotive smart switches, CAN transceivers, motor drivers

Discrete & Power Modules

- MOSFET, IGBT, diodes, BJTs

- Consumer SPM/IPM, industrial solar/UPS/motors, automotive HEV/IEV/SSV

Converters and Mixed-Signal

- Low-speed/high resolution D/A converters, high-speed D/A converters, low speed/high resolution A/D converters, high-speed A/D converters, CODECs

Configurations

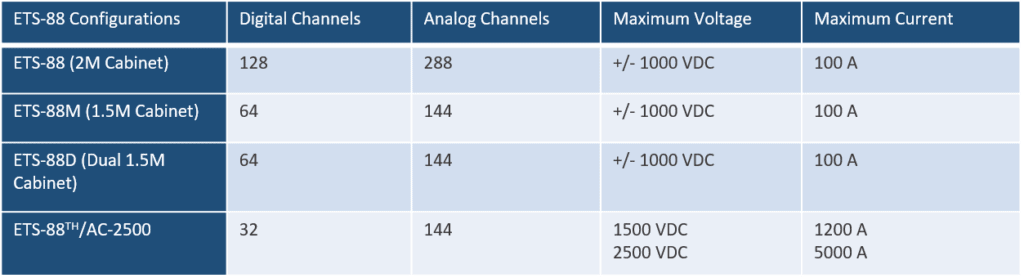

The ETS-88 multiple test head architecture provides the flexibility to reconfigure the test system using software control. The system is comprised of dual sector test head card cages for up to four sectors depending upon system configuration. Each set of sectors can be bridged together within the test head card cage on an application-by-application basis. The sectors can be configured to operate independently, running unrelated applications if desired, or can all be bridged together to expand the site count of multi-site applications.

The system is controlled using a multi-core PC to maintain isolation between applications. This control method lets you assign cores and test heads to applications for the greatest test efficiency, and provides the ability to support single site, multi-site, and I.P. applications from a common base platform.

ETS-88 Standard Configuration (Up to four sectors)

- Up to 32 digital channels

- Six floating resource slots for up to 72 analog channels

- 32 C-Bits

- Eight programmable master clock channels

ETS-88TH/AC-2500 Configuration (two sectors)

- 12 Floating resource slots (six per sector)

- One DPU-16 instrument per sector (32 pins total)

- Two HPU instruments per sector (400 A total)

- AC-2500 card cage

- AC instruments

- Matrices

- Electronic motor DIB actuator

Instrument Options

The ETS-88 test system is a general purpose precision analog and mixed-signal test platform designed for high volume production testing of integrated circuits. The system is optimized for high throughput applications, with a fully integrated multisite software and hardware architecture. The ETS-88 test system offers high precision and high accuracy test capabilities. Test speed is only of value if the results are trustworthy. As such, the ETS-88 test system provides both measurement speed and high accuracy, following the ETS tester tradition of providing high precision test capabilities with a robust assortment of available instruments such as V/Is, DC/AC voltmeters, digitizers, AWGs, digital pin electronics, and time measurement instruments, all optimized for multisite testing.

8×8 MATRIX: High voltage force / sense crosspoint matrix; any input channel can be connected to any output channel

APU-12: 12 channel, four quadrant V/I with six current ranges ranging from 200 mA to 10 uA at +/-30 V

CAMII: Instrument module designed to measure capacitance in the sub-picofarad range

DPU-16: 16 digital I/O channels supporting vector rates up to 132 MHz with 8M of standard vector memory

HCU-2000: One channel, 2000A rack mounted resource for ETS-88DUO Testhead with innovative interposer connection for fast and reliable high mechanical endurance connection and disconnection to the DUT Board.

HPU-100: Single channel V/I with 10 current ranges operating up to +/-100 V

MPU-120: Four quadrants V/I with built in 16-bit digitizer capable of forcing voltage up to 120 V and current force up to 40 Amps

QHSU: Two fully independent dual channel high-speed signal analyzers capable of source or measure up to 50 MHz

QMS / QMS-T: Four precision (12-bit at 10 Msps or 16-bit at 200 ksps) independent floating differential volt meters that support AC and DC measurements up to +/-200 V

QPLU: Low noise, analog source and measure resource with 1 PPM (20 bit) accuracy with 381nV resolution

QTMU: 8 independent time measurement units multiplexed to digital pins with a start/stop and arm signal per sequencer

SPECII: Test head expansion, relocating high power instruments to the mainframe cabinet

SPU Family (100, 112, 500): A suite of V/I’s capable of addressing a wide range of test requirements ranging from 100V / 2A to 500V / 50mA with fully AWG and digitizing capabilities per channel

WCU-2220: Waveform capture instrument with full scale sensitivity from 0.2V to 2000V at 8-bit resolution with a decade of programmable offset available per range

Software

The ETS software development environment and tool set are truly one of the strongest attributes of the ETS-88 test system. The software tools are easy to learn and use, and are fully integrated into the Microsoft Visual Studio development environment. The complete test system command set is supported with automatic code generation tools (ACE™ and GrACE™). This means that users are not required to memorize command arguments and syntax. Graphical plotting tools are provided for simple point-and-click plotting of test-oriented waveforms. RAIDE™ (Rapid Access Interactive Debug Environment) makes it easy to view and change tester hardware settings.

ETS’s software provides a robust test development environment, offering customers an easy learning curve and uncommon productivity. There are two versions of the software: EV and EV-MST. Referring to multi-sector technology, EV-MST allows users to replicate test programs across multiple test head sectors. The standard ETS-88 test system supports both software suites. Adding options, such as the AC-2500, may change which suite is supported.

EV & EV-MST Graphical Test Programming Environment

EV Key Features

- Innovative, easy to use graphical methodology for controlling test system resources

- Fully integrated plotting tools

- EV advanced software tools for uncommon productivity

- Fully support multisite parallel testing

- Complete support of pattern-based testing

- Graphical programming methods reduce time-to-market through the introduction of simple and easy to operate tools

EV-MST Key Features

- EV-MST software architecture supports different modes of operation

- Simultaneous independent applications

- Each application can itself be multisite

- Keeps tester utilization high by continuing to run other applications during changeover

- Traditional multisite applications with synchronized testing on multisite handlers

- Independent communications channels allow near 100% multisite efficiency

- Full index parallel testing that maximizes turret handler throughput

- Specialized datalog handling combines DUT data from different sequential stations

- 100% resource independent QA test

As the leading provider of complete Test Cell Solutions and services, we at Teradyne leverage our expertise, experience, and technology leadership to help our customers achieve the highest yield and the highest throughput in production with the fastest time to market. We partner with you in your journey from design to production to provide standard and customized test cell products and services.