Who We Are

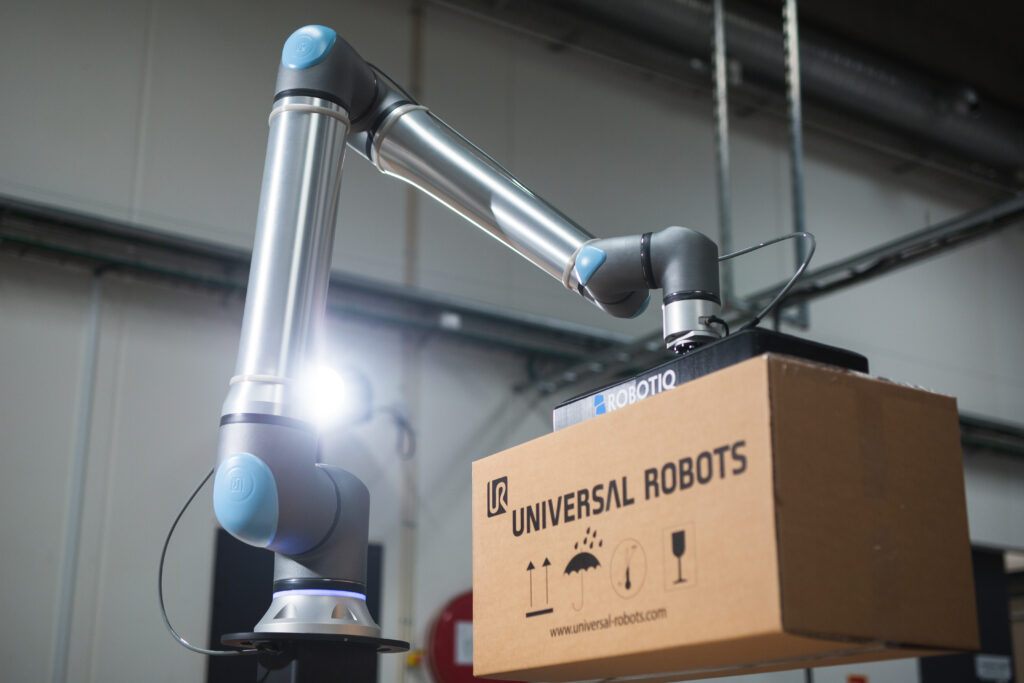

Teradyne Robotics, a division of Teradyne, is a global leader in advanced robotic solutions. It is comprised of Universal Robots and Mobile Industrial Robots (MiR) who empower businesses of all sizes to enhance operational efficiency by integrating the power of machines with human talent. Our comprehensive range of solutions enables companies to optimize manufacturing processes, leading to improved product quality, increased productivity, while greatly improving worker safety.