Home | A Real-world Use Case for the Industry’s First Fully Automated System Level Test Platform with Integrated RF Test Instrumentation

← Go back

System Level Test (SLT) is testing a device under test (DUT) in an environment that closely matches its final use. The growing complexity of SOCs and SIPs, combined with increasingly stringent quality requirements, has led to wider adoption of SLT as a key advantage in device test strategies.

By using SLT to functionally test a device that matches its final use environment, device manufacturers can prevent fault escapes that might not have been detected with traditional wafer and package test techniques. Teradyne has responded to industry trends to enable testing of various Radio Frequency (RF) functionalities by developing the industry’s first RF-enabled high-volume SLT tester, Titan-RF. RF testing in SLT is a highly desired trend but hard to realize due to the complexity and scalability of RF solutions.

The Challenge

Device manufacturers are seeking to integrate RF testing capability into System Level Test. Mobile devices have transceivers that send and receive RF signals. Device manufacturers need to establish the performance and maximize signal strength of these devices while not exceeding specified government requirements. These device manufacturers require a test solution that enables their devices to be connected to a vector signal generator and vector signal analyzer (VSG/VSA) to perform RF power level calibration for broadband signals. This device and VSG/VSA need to be connected to the system level tester to do the final functional test.

Traditionally this type of test was done at the bench manually since VSG/VSA must be connected one at a time, which results in low productivity and impractical space utilization to realize mass volume.

The Teradyne Solution

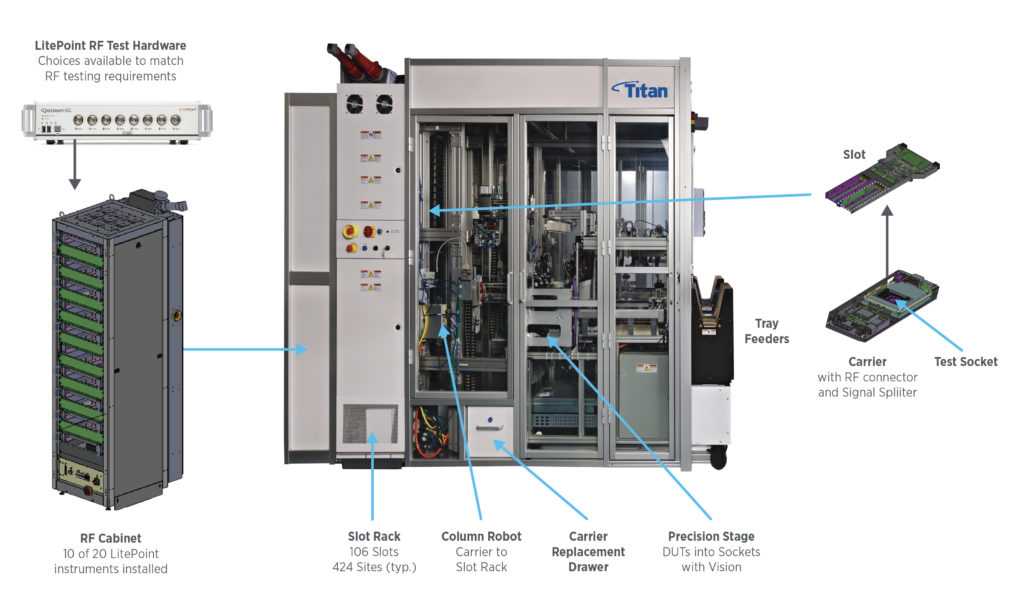

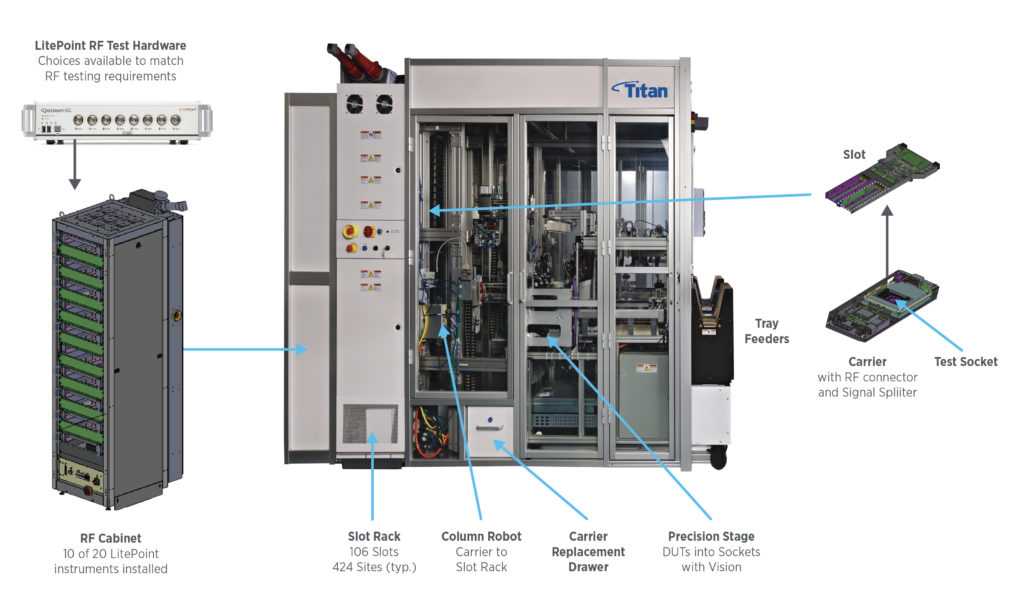

Teradyne’s Titan-RF SLT tester delivers a massively parallel, automated, asynchronous tester for devices that require RF connectivity. The Titan RF SLT platform supports up to 320 RF-enabled test sites. Additionally, Teradyne has developed miniature wideband RF signal splitters to deliver up to 12 RF signals per DUT. The RF testing functionality is provided by integrating with test instrumentation from LitePoint, a Teradyne company, located in an attached support cabinet. A wide range of RF test instruments are available from LitePoint to meet the required test performance and capability.

By using the Titan SLT platform with integrated RF test, device manufacturers are able to validate devices by performing a full system level functional test, execute a test call over each sub-six GHz LTE band and determine power level calibration requirements.

Solution Highlights:

- Supports up to 320 RF-enabled test sites

- Automated, repeatable RF blind-mate interconnect that performs over 50,000 insertions before maintenance

- Miniaturized RF signal splitter to distribute up to 12 RF signals per site over a wide frequency range (600 MHz to 6 GHz)

- Fully automated asynchronous RF test system with automatic self-calibration

Solution Benefits

With the Titan-RF solution, device manufacturers can:

- Perform parallel testing with high site count while still meeting their RF testing requirements with high repeatability and less human error

- Achieve floor space savings of nearly 90% vs. existing solutions

- Achieve operator labor savings of up to 86%, assuming 1 operator supports 4 Titan-RF systems

- Maximize the device RF performance by characterizing the device in the final system level application environment

The Deployment

The Titan-RF SLT platform is fully automated. DUTs arrive in standard JEDEC trays. From there, the test process is streamlined through a series of automated handling steps whereby the devices, in their carriers, are connected to test instrumentation located in test slots arranged in a vertical rack that optimizes factory floor space.

The Titan-RF SLT software applies the test program to the DUT, leveraging the LitePoint RF test instrumentation to perform connectivity, calibration, compliance and other types of tests required. With the device test program complete, the carrier is removed from the test slot and returned to the automation area of the Titan-RF SLT system where the tested devices are removed from their carriers and binned accordingly.