![]()

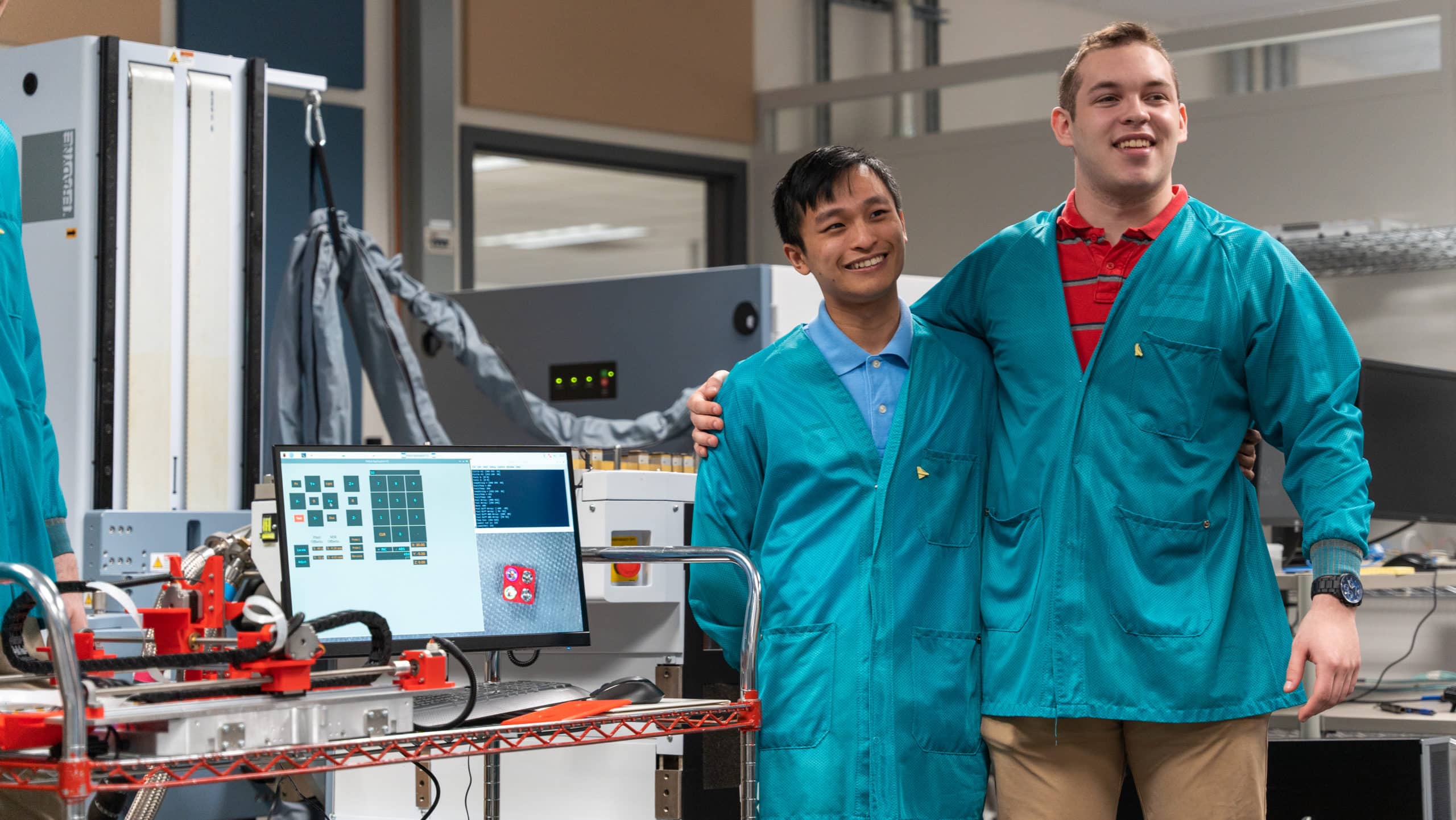

As part of Teradyne’s on-going efforts to encourage STEM programs in high schools and at the university level, we’re proud to partner with Wentworth Institute of Technology. This year we worked with a team of 5th year capstone electro-mechanical engineering students at WIT to support the design and build of a calibration robot with the goal of automating a test procedure for 5G mm wave chips. Brian Wadell, Senior Staff Engineer at Teradyne, has been leading the project with WIT Professor James McCusker, and the team of students; James Voss, Marcel Almonte, Gregory Troop, and Wesley Le.

The robot is cartesian style, meaning it is a machine with three axes perpendicular to each other that move linearly. This enables the robot to perform with the utmost precision and accuracy. The project did face some challenges including finding accurate and reliable motion feedback, system control, interfacing with existing hardware and software, handling delicate coaxial connectors, and automating failure detection. With the many challenges that come with creating a robot of this caliber, the team has been working diligently since the fall of 2021 to overcome barriers and deliver the best solution for the challenge.

“Working with WIT is Teradyne’s opportunity to influence students entering the workforce to enter the Automated Test Equipment field. We can show them the kind of interesting problems we are challenged with every day and supplement their WIT learning experience,” says Brian Wadell.

Not only is the project supporting Wentworth students, but it also benefitting Teradyne, because the students’ research is helping solve some real technical challenges that we are working on. With Teradyne’s expertise in the field, it has truly made a positive impact in this group of students’ robotics mission at Wentworth. According to the students’ professor, James McCusker, Ph.D., “The growth of the students throughout this experience is something that could not be emulated purely in a classroom setting and I am truly thankful to Teradyne and Brian Wadell for facilitating this for our students.

The students have found tremendous value in this first-hand experience and have grown a lot within the nine months they have spent working with Teradyne. “As I reflect on our opportunity to work with Teradyne for our senior capstone project, it has been nothing short of amazing. The capstone is an opportunity to show what we have learned over the past 4 years, and having a company like Teradyne to provide a well-defined problem played a massive role in our success.

Our representative from Teradyne, Brian Wadell, provided industry specific insights that allowed us to be extremely effective in designing a solution, and the engineering resources that were made available to us through Teradyne allowed us to focus on creating the best product possible. We are thrilled to be passing our Cartesian Robot to them in April, and to pursue professional opportunities with them after graduation,” says capstone student James Voss.

“Working with Teradyne to create a Cartesian robot for my capstone has been a challenging and rewarding experience. With lots of determination, I’ve been able to apply my knowledge of feedback learned in the classroom to an image processing module to control the robot. Image processing is one technique that can be used for process automation. My passion lies in manufacturing and this valuable skill is something that I can transfer into the professional world and I couldn’t have done it without the support of Teradyne. I would like to give a huge thanks to Brian Wadell for mentoring me and my group on this journey,” says capstone student Wesley Le.

All Photos by Matthew Conde