LEMSYS SLIC-AC

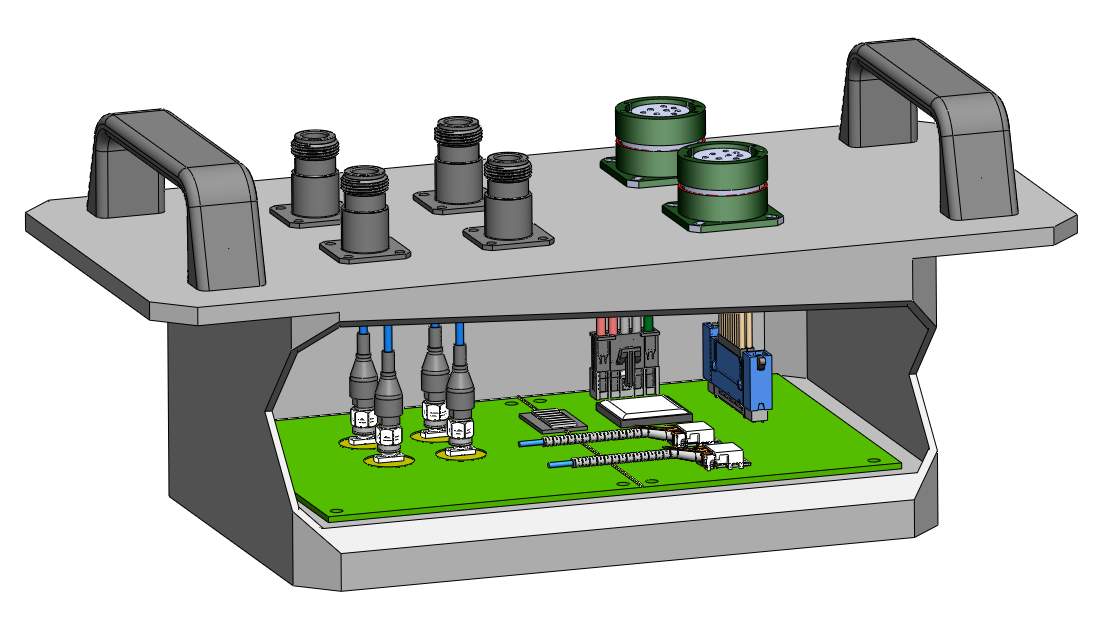

LEMSYS SLIC-AC Platform

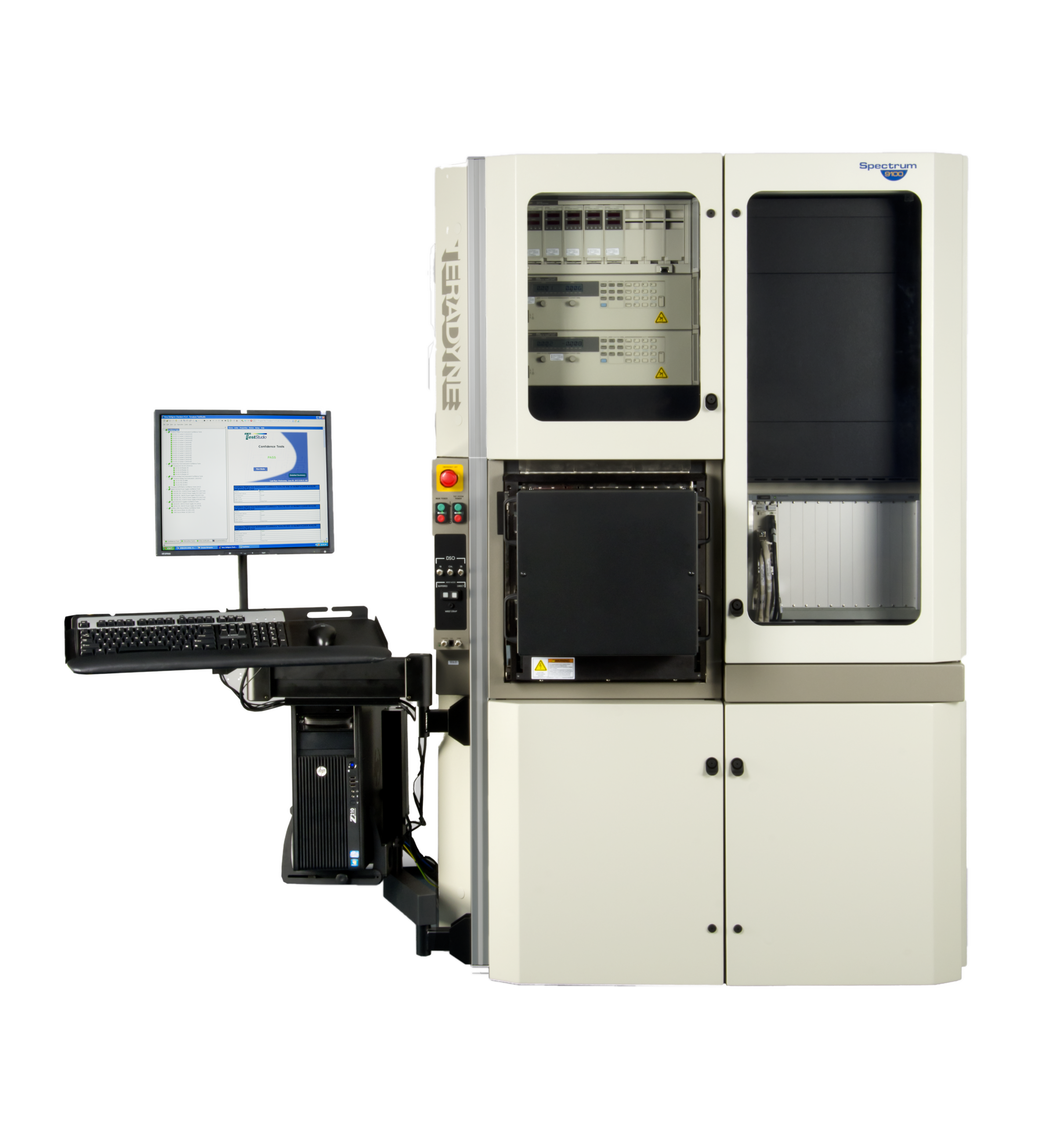

The SLIC-AC is specifically designed to test the switching characteristics of the latest generation SiC Automotive power modules, with maximum short-circuit currents up to 12kA.

Advantages

High Test Quality

- Optimized DUT interface similar to the EV propulsion system

- Consistent, high quality test results with clean waveforms

- Low voltage droop during short-circuit tests

Easy to Operate

- Intuitive user interface

- Can be manually operated without an engineer

- Can be used with any handler in a production line

Short Time to Market

- Standard product design

- Customizations for different DUT types is done via the DUT interface

- In production within a day

Secure & Easy to Support

- High reliability with uninterrupted operation for production

- Increased quality due to standard product design

- Minimal parts maintenance

Applications

- Automotive propulsion systems

- Automotive charging stations

- High-power power modules for industrial drive systems

- Three level solar power modules

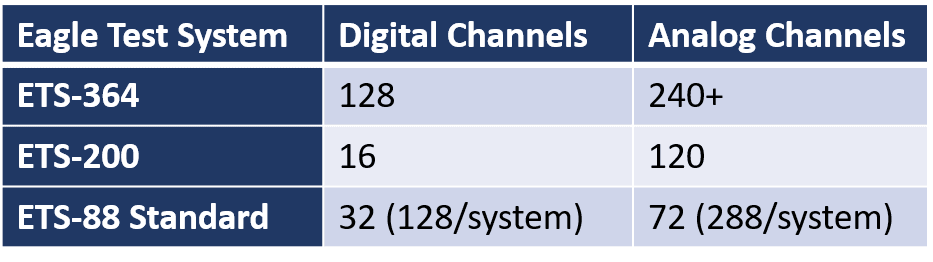

Configurations

For complex IGBT/MOSFET power modules, the SLIC-AC tester includes a cabinet with the power generator, inductive loads, Windows PC, and power supply. The DUT interface board is connected to the power output terminals on the front of the cabinet and can be changed in less than 2 minutes for testing different types of power modules.

Tests available

- Gate contact

- Single pulse RBSOA

- Double pulse RBSOA

- Double pulse Turn OFF-ON-OFF

- Turn ON on inductive load

- Turn Off on inductive load

- Qrr on Free-Wheeling Diode

- Eas or UIL avaleng

- Qg(on), Qge, Qgc

- Short-circuit SCSOA1 (with opposite DUT or Aux switch)

- Short-circuit SCSOA2 (with opposite DUT or Aux switch)

System Options

- Operating System: Windows 10 Pro 64-bit or higher.

- Flexible hardware and software options with object-oriented programming.

- Test results and test parameter data available in CSV and XML formats.

- Easy creation and editing of test sequences.

- C# coding access for specific characterization sequences.

- Pass/Fail and classification into categories.

- Self-check system diagnostics.

- Multi-level user profiles

- Quick installation of updates to minimize downtime.

- Statistics displayed in real time.

- Remote software upgrades and hardware diagnostics.

- Tester remote control via OPC server (with OPC license).

- On-screen visualization and the ability to save oscillograms.

- Remote control of the oscilloscope via the desktop PC.